Precision Casting and Fusion Delivers Unparalleled Cleanliness and Timeless Finish

From our earliest days, we have recognised the importance of precision casting and fusion processes in creating clean, high quality products. Every product that emerges from our factory is finished to an exceptional level of detail and is met with the highest standards.

Precision Casting

The Premier Choice in Precision Casting

Precision casting is one of the highest quality castings that offers freedom in design and material selection. With tight tolerances and high-quality finishes, precision casting produces highly accurate parts while maintaining an excellent finish. While it is renowned for producing the highest quality castings, it involves additional costs and time due to the intricate process steps, making it less cost-effective for low-quantity productions. Despite these considerations, precision casting remains an ideal choice for requiring intricate and high-quality finished products.

Precision Casting Takes Great Human Skill and Attention

All of our products go through our artisans, where years of experience and passion is met. It is only by following this that our products are approved and meet our expected standards.

Quality That Needs to be Experienced First Hand

We turn raw materials into perfectly sized products that can handle heat and withstand the tests of time.

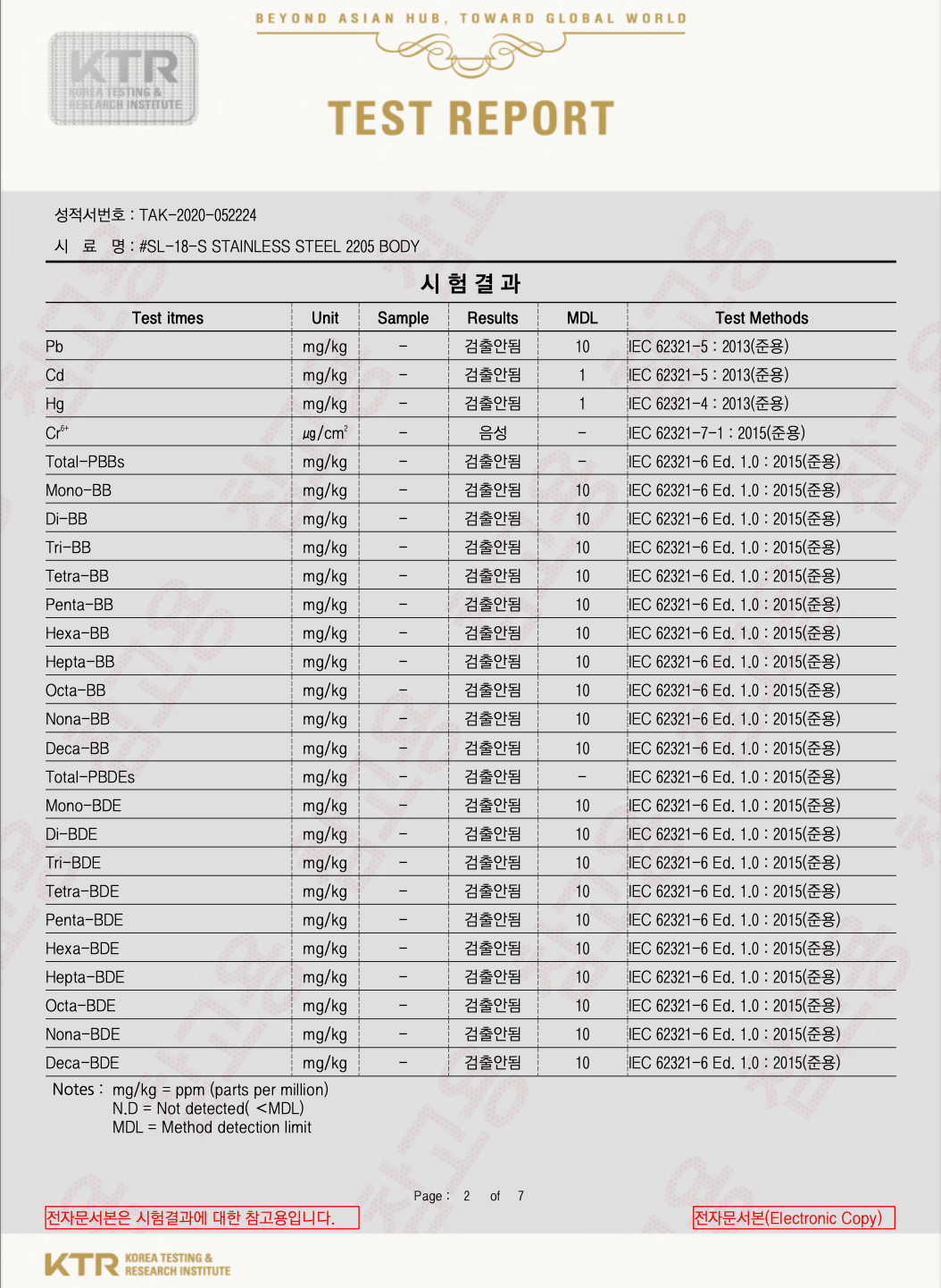

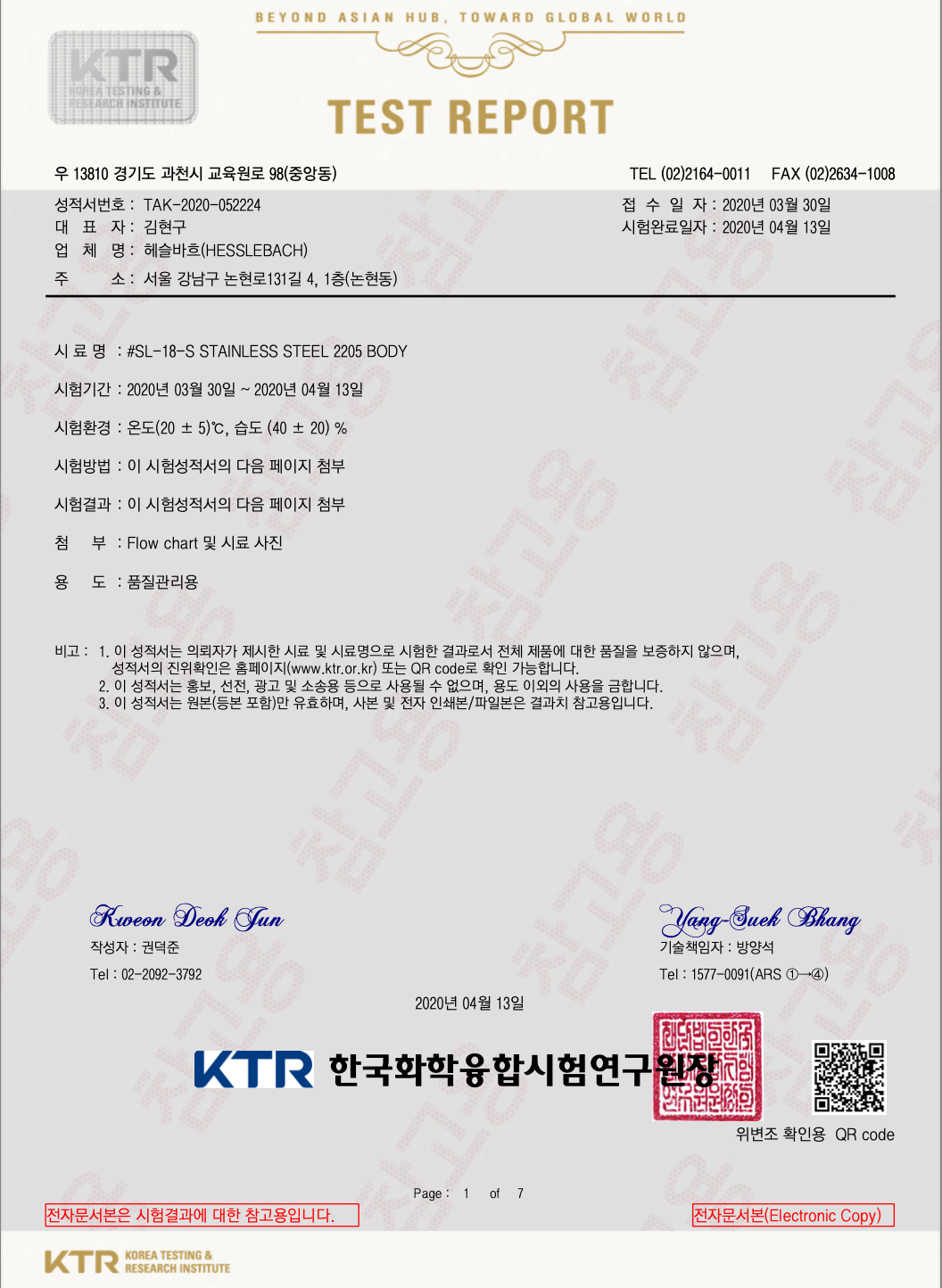

Thanks to our innovative solution, PuraSteel™, Hesslebach's core body is highly resistant to acidic compounds, ensuring worry-free cooking. It also boasts exceptional resistance to corrosion, eliminating concerns about rust.

Plus, it's free from PTFE, PFOA, and harmful metals.

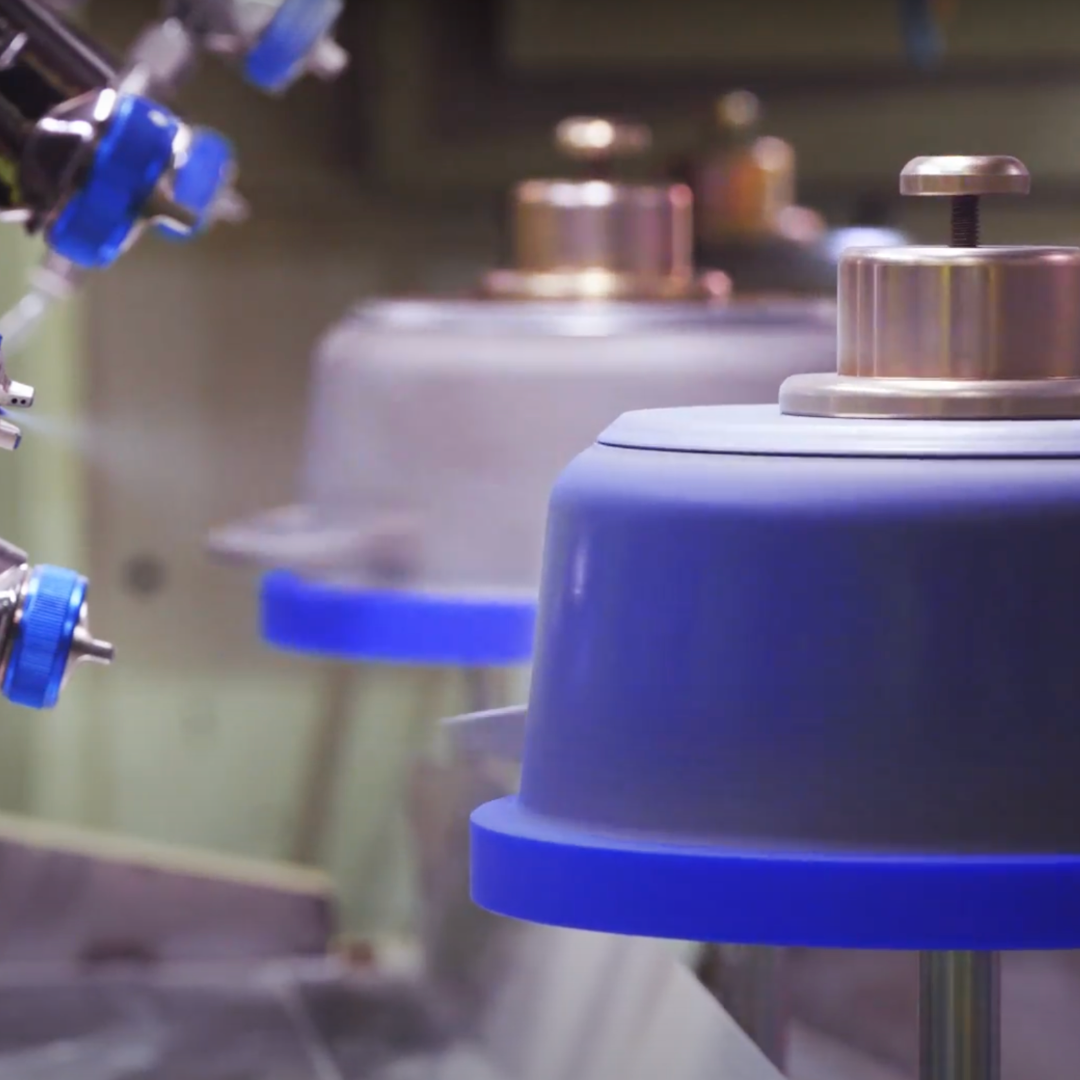

Unique Fusion Process That Makes Cleaner Cooking Possible

Unlike many cookware brands that apply their 'non-toxic' coating only on the exterior for a non-stick effect, we integrate our 100% ceramic coating, PuraCotta™, directly into the PuraSteel™ body. This ensures a non-toxic layer that won't peel, providing a natural non-stick surface to keep your food safe.

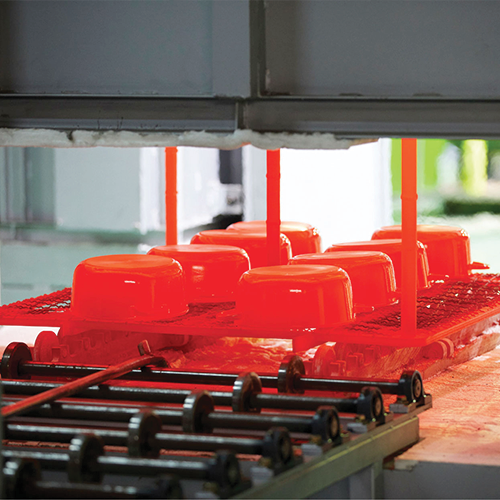

Fusion

The Ultimate Cleansing Process, Delivering Cleaner Cooking and Quality

Our fusing process involves three intense heating processes. We start by coating the PuraSteel™ body with the PuraCotta™ solution, followed by combining them under intense heat of 1,475°F. This entire process is repeated three times, ensuring safe cooking up to 650°F. Throughout this meticulous process, the coatings permeate the stainless steel body, fusing it together instead of being layered.

As the product undergoes the fusing process, harmful chemical particles are completely incinerated, reinforcing Hesslebach's commitment to providing clean and safe products.

Our Fusing Process is Essential For All of Our Products

Our fusing technique is pivotal to every Hesslebach product. The seamless fusion of PuraSteel and PuraCotta determines the creation of our flawless final product. Every component is crafted to be clean and non-toxic, from the stainless steel body to the coating, and from the screwless design to the choice of exterior colors. Each element is meticulously designed with your health and safety as our top priority.

The Hesslebach way has been a pursuit, attempted by many but never achieved until now.

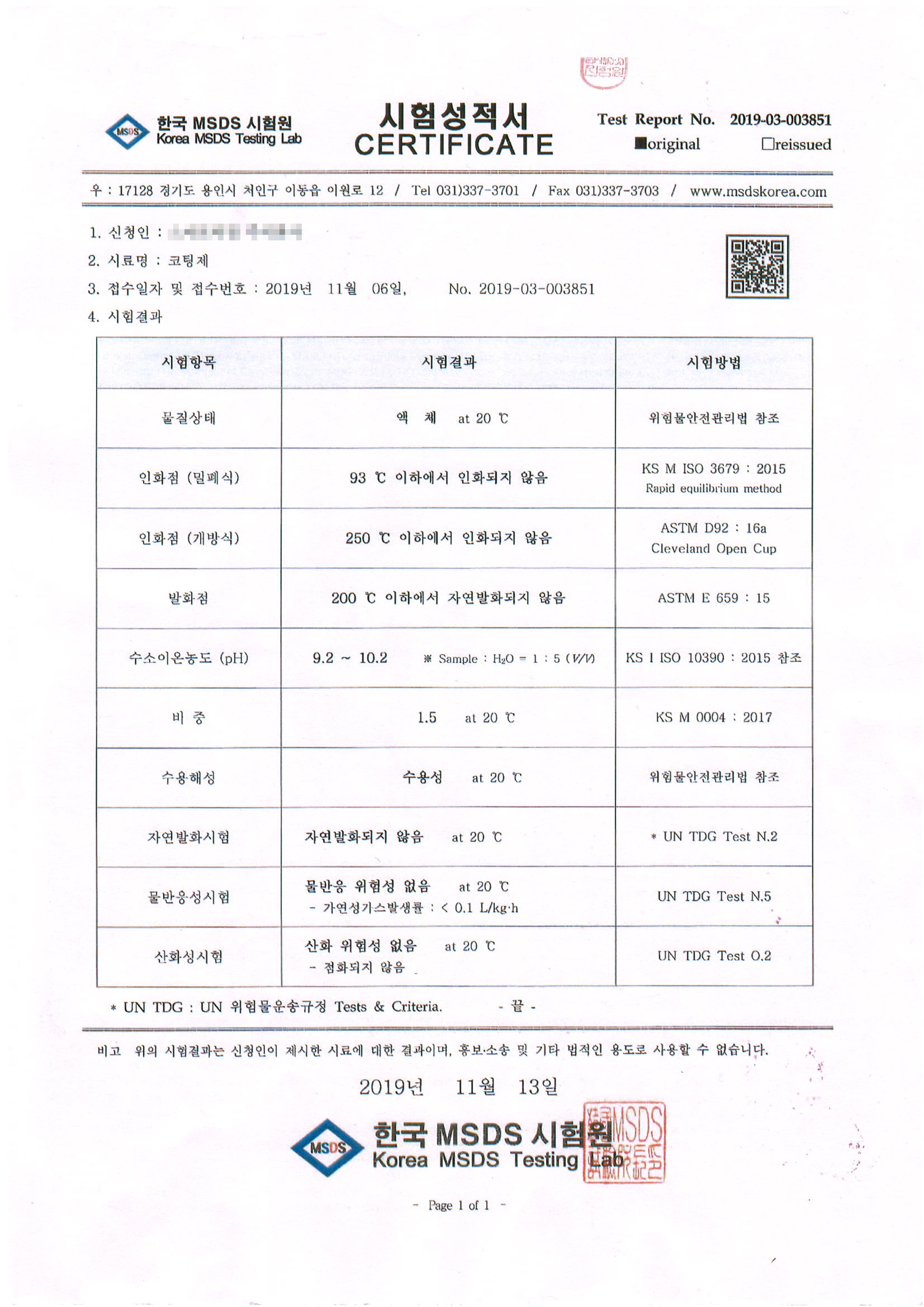

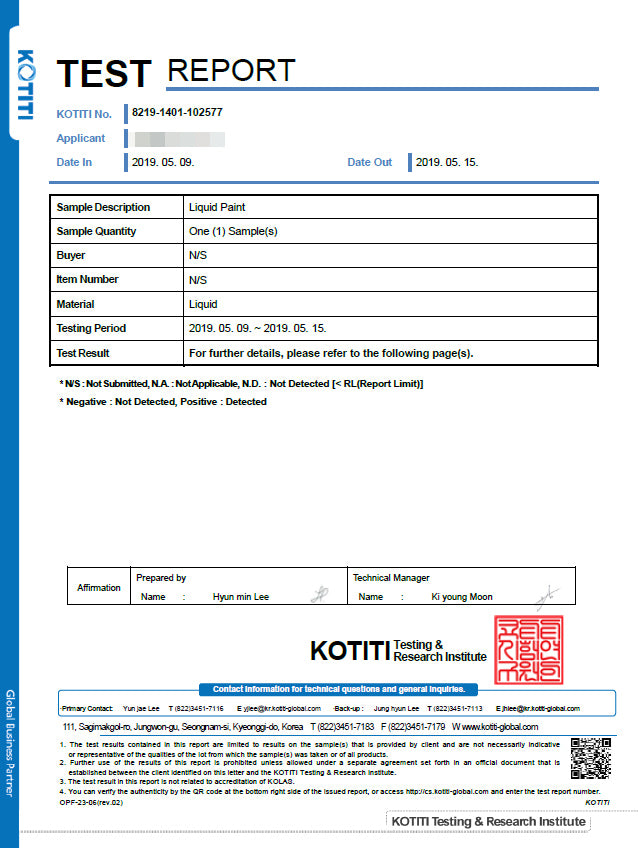

Verifications

Our Stories

Often attempted but never solved

Hesslebach has done it